Wood Construction and Carpentry

No sanding, just planed or rough-sawn? These times are long gone. Architects and customers expect best visual quality even on load-carrying components - and this means: Sanding. Kündig offers specialised widebelt sanders for wood construction purposes which can handle the weight and size of laminated beams and the like.

Solid Solution for Timber Construction

Due to the nature of timber construction, workpieces usually tend to be very heavy. That's why they are often being sanded by hand. Manual assembly has long been replaced by automated timber processing machinery. So why not make the next step and upgrade the sander? Industry experts agree that in addition to every automated assembly system, a wide belt sander should nowadays be included in order to work efficiently and meet the growing demands regarding surface quality.

Easy Handling

All operations and adjustments are easily attainable - depending on preference, Kündig Machines can be operated fully automatically, with custom automated sanding programmes, or manually, by adjusting all relevant parameters on the go. Built in safety measures eliminate the risk of major accidental operating errors. Kündig sanders are well appreciated for their easy handling.

Powerful Drive for heavy Tasks

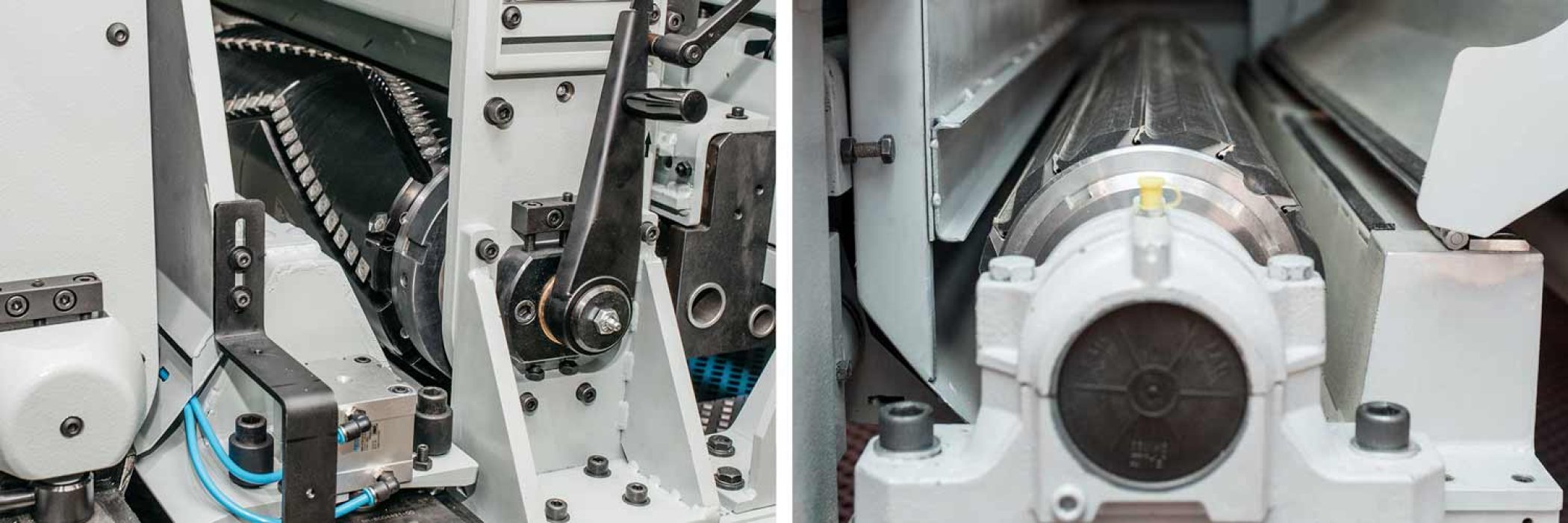

The units of our sanding machines can, if useful, be upgraded to 100 kW. An economic, energy saving control system accurately adjusts the output to speed and load needed. Many options like calibration rollers, pneumatic and electronically controlled, segmented pads or brushes are available.

Thanks to the fact that only the upper machine section is moving, the working height stays fixed and the passing height allows for very high work pieces of up to 500 mm (20 inch) to be processed. Additional handling tables that allow easy handling of heavy workpieces with a forklift can be added. To facilitate handling and multiple sanding passes of heavy workpieces, there is a reverse function available which allows to reverse the conveyor direction so that workpieces can be sanded multiple times without lifting them out of the machine.

Unit Options

Calibration Roller

Steel or rubberised, in different diameters and with different belt lengths: 1900, 2000, 2620, 3250 mm.

Brushes

Either as add-on or as an integrated unit with a variety of brush roller types for sanding, structuring, cleaning from dust. With or without oscillation. A carousel unit for sanding of three dimensional workpiece surfaces or the rounding of edges.

Planer Unit

For planing or calibrating, usually before finishing the workpiece by sanding it. Different versions available for working widths: 650, 1100, 1350, 1600 mm.

Watch Video

Timber Construction specific Options

|

Table enhancement The inlet and outlet table enhancement for the machine assists with handling of particularly large workpieces, like doors or big windows. The elaborate construction allows quick, space-saving stowage of both collapsible tables. |

|

Extra Inlet Height Allows for sanding of very thick workpieces up to 500mm (20inches) |

|

Workpiece Retraction Facilitates handling of heavy workpieces by allowing the operator to reverse conveyor belt direction if multiple passes are required. |

Stair Construction

Simply put, Kündig's exclusive oblique sanding technology improves benefits for the sanding of stairs: Through slanting of the sanding assembly, the sanding grit's cutting ability and belt life improves, also undesirable sanding traces don't show on the work piece. According to experienced users, Kündig's oblique sanding technology is a perfect match for stair construction applications. Hence, the Kündig Brilliant is very common among stair constructors. And it's not only the impeccable sanding performance, the machines are very rugged and can handle very heavy stair strings with ease.